VoitchovskySàrl

VoitchovskySàrl

Our Company

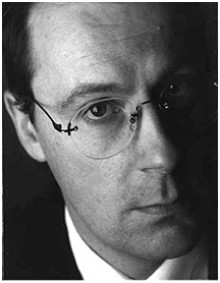

Director

Maurice Neri

Chemical Engineer

Art and matter

Specialists since 1989, we have acquired an experience that has allowed us to test many formulas. We have learned to deal with the requirements and particularities of polished concrete. Our profession comes from both traditional masonry and interior decoration. We combine technique, aesthetics, art and craft.

Polished concrete: an exceptional material for timeless coatings

We have more than 2000 projects to our credit. It is more than 20 years of experience that have allowed us to select the best products, to develop techniques and know-how for high quality realisations of impeccable quality.

Contemporary atmosphere

A little history: From 1990 to 1995, we specialized in decorative lime-based wall coverings (better known as Venetian stucco, Florentine stucco, glazed and waxed lime, etc.) in order to create materials and textures different from those available on the market.

Since 1995, the trend of decorative coverings for interiors has been introduced in specialized magazines, replacing traditional floor coverings such as tiles, parquet etc.

They are known under various names: glazed screeds, tinted concrete, waxed screed, waxed concrete, polished concrete. The first approach to this type of surface condition was mainly based on coatings with a thickness of 8 to 10 cm, more or less glazed, with a somewhat rough finish. The protection of the surface condition was ensured by the application of natural wax and vegetable oil. Surface renderings (finished surfaces) were often uneven, and customers were dissatisfied with the result.

Then we had the arrival of decorative mortars with a thickness of 1 to 2 cm. Their rendering allowed for less coarse creations but still raised serious questions about their ability to be renovated in the event of stains or damage.

Since 1998, we have followed this trend and sought to develop a coating system allowing for easier to manage projects, with solutions guaranteeing durability, renovation and maintenance during use.

After many tests, we were able to realize our current product.

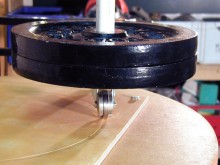

Wear test

When it comes to dirt protection, even though our coating is compatible with waxes, oils or impregnation, we have opted for a two-component varnish-based sealing system to ensure optimal protection of our coating.