VoitchovskySàrl

VoitchovskySàrl

Implementation of polished concrete

The preparation and quality of the support must be given particular attention in order to ensure the durability of the polished concrete coating and to avoid the appearance of cracks. :

For new surfaces :

Comply with the standards and professional rules relating to the technique of laying surfaces (EN 13813, DIN, VOB, Ö-Norme, SIA).

The high-strength mineral mortar is compatible with all types of surfaces. For Switzerland, they must comply with the SIA V567-251 standard.

Particular attention must be paid to the requirements of SIA V567-251 - 2.4, 2.46 and 2.47. — 5.7 to 5.74.

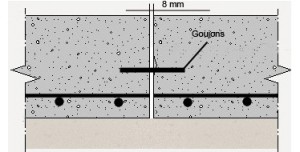

Peripheral expansion joints, like field separation joints, must be through joints and have an edge strip at least 8 mm thick.

Field separation joints :

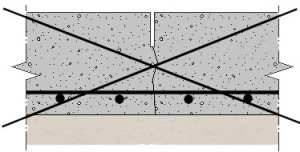

Fig A

Fig A

Fig B

Fig B

- Fig A - Shrinkage joints in this form should be avoided.

- Fig B - The field joints must be through and include an edge strip

The surface segments will be doweled to minimise tiling.

Expansion joint(s) at doorways :

- Expansion joints at doorways must be treated like field separation joints.

- They must be through and have an edge strip at least 8 mm thick.

- They must be doweled with the adjacent clevis segments.

Important :

- Particular attention must be paid to the position of the expansion joint so that it is below the axis of the door.

- Clearly specify the transition heights in relation to the adjacent covering (parquet, tiles, stone, etc.).

- The thickness of our coating with the preparation layers is 5 to 6 mm

Surface area of fields for cement-based coatings :

The cement-based coatings will be cut into fields; the joints will be distributed according to the support, among other things, while respecting the following indicative values: :

Field surface

Field length

Relationship between sides

Without underfloor heating

maximum 40m²

maximum 8m²

maximum 1:2

With underfloor heating

maximum 30m²

maximum 6m²

maximum 1:1.5

Surface of fields for synthetic or calcium sulfate-based coatings

The expansion of these different coatings can vary depending on their composition and the materials used. Refer to the technical data sheets of the different suppliers for the recommended surface area of the fields.

As a precaution, it is better to "partition" and balance the different surfaces with several segments of screed in order to avoid the appearance of cracks in the coating.

Required surface quality

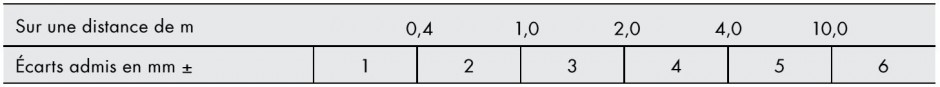

The level tolerance with respect to the theoretical dimension is ± 5 mm. In addition, the planimetry deviations will not exceed the following values: :

Edge Lifting (Tiling Phenomenon)

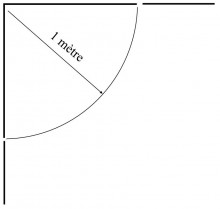

The above tolerances do not apply to the elevations of the edges of cement-based screeds. For planimetry control, the measurement points will be taken at a minimum distance of 1 m from the corners of the fields defined below. :

Unevenness along the edges, caused by the raising of the edges of cement-based screeds, shall not exceed 5 mm; reverse deformations shall not exceed 7 mm.

The edge lift is measured relative to a reference line drawn between two opposite corners of the field.

The maximum permissible distance between this line and the surface is 5 mm, which can be added to the planimetry tolerances defined above.

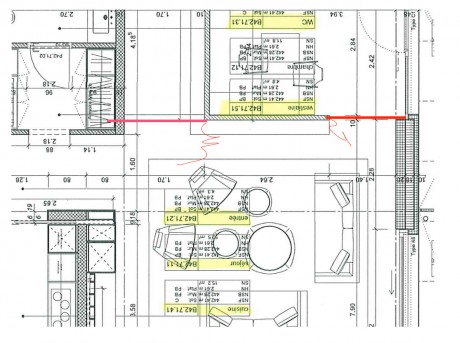

Checking the position of expansion joints

Carefully check the presence of expansion joints in order to avoid as much as possible the presence of protruding angles in the screeds leading to the appearance of cracks.

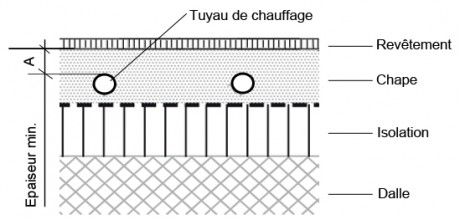

Coating thicknesses over underfloor heating

Cote A = Minimum coating thickness above underfloor heating :

A = Cement coating : 60 mm min. / Anhydrite coating : 50 mm min

Soil moisture, high residual moisture: (measurement with CM device)

To avoid further deterioration of our coating, here are the maximum humidity standards in the substrate :

Maximum water content for cement-based screeds :

- With or without underfloor heating max. 1,5 %*

Normal mortar and fluid mortar based on calcium sulphate (anhydrite)

- Without underfloor heating : max.0,5 %*

- With underfloor heating : max.0,3 %*

Remark :

- A drying time is provisioned: 1 week per cm of thickness of cement screed :

- A drying time is provisioned: 1.5 weeks per cm of thickness of anhydrite screed :

These values are to be taken as indicative. Drying times can vary considerably depending on the ambient temperature, the ventilation of the premises and the density of the coating.

Ambient climate

The ideal floor temperature for the coating is between 15 and 24 °C

The relative humidity of the air is ideally between 45% and 65%

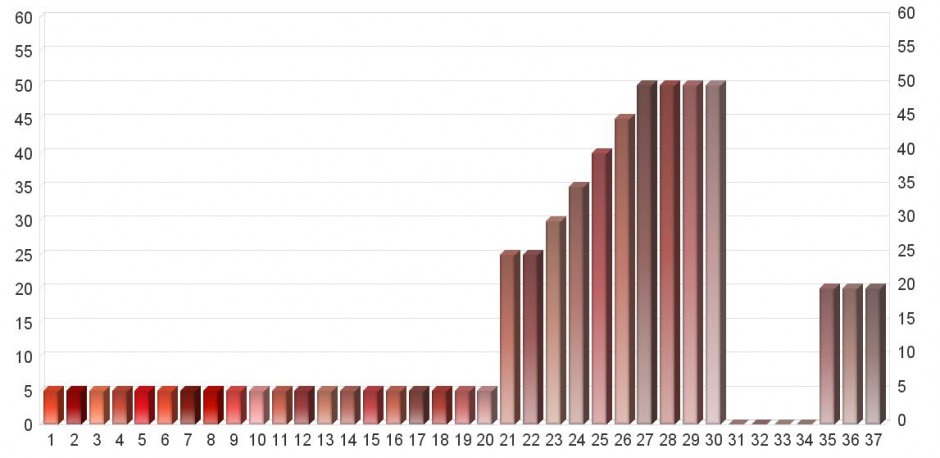

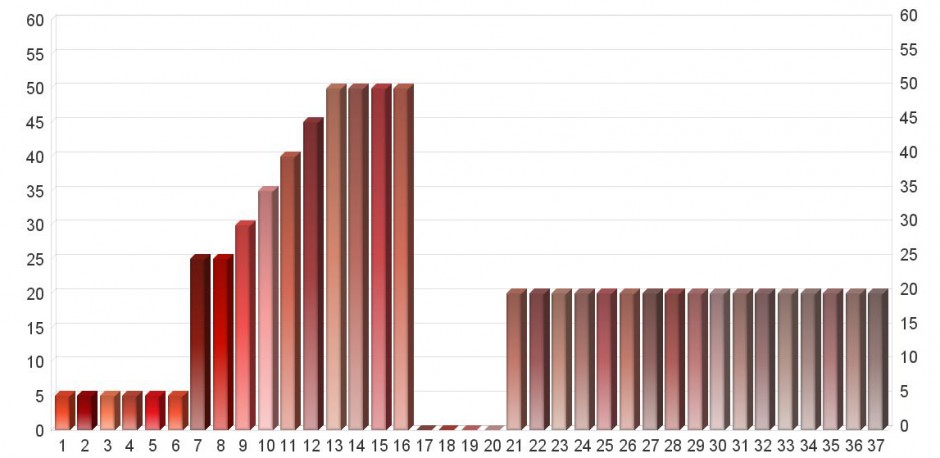

Example of a protocol for underfloor heating

Underfloor heating temperature raising process for cement-based surfaces

Underfloor heating temperature raising process for calcium sulphate (Anhydrite) surfaces

Surface under renovation

The existing surface must be stable. If cracks are present, the cause must be determined and the stability of the surface verified. Cracks must be repaired using two-component epoxy resin.

The redressing of the grooves left by old partitions or the passage of electrical connections is undertaken using two-component epoxy resin-based mortar in order to avoid shrinkage or cracking. The thickness of the cover must be at least 3 centimetres above the pipes to avoid the possibility of settlement.

Existing tiles

It must be stable and well glued. There should be no cracks in the tiles.

If cracks are present, they must be investigated. They often come from poor workmanship in the implementation of the tiles. This may be due to the peripheral expansion joints that have been sealed with the cement mortar used for the tile joints, which prevent any expansion of the surface and its coating.

Preparatory work includes the curving of the periphery of tiles to accommodate expansion of the covering.

An inspection of the tiles must be carried out to check their retention and any cracks must be sealed with epoxy resin.

Wooden floors and parquet are not compatible with our cladding. This is because micro-cracks in the coating can be caused by the expansion of wood in the presence of moisture contained in the mortar. However, in the case of use with moisture-resistant hydrophobic or phenol wood, the coating can be applied with certain specific preparations to furniture, kitchen countertops and washbasin shelves.

- For the floor - Fermacell or Knauf type panels (dry surface) Our system is compatible with this type of panel. It should be noted that the sealing of the plates with a adhesive mortar, reinforced with synthetic resins, must be used and applied with great rigor. The joints between the panels will be covered with a high-strength mortar.

- For the walls - Fermacell panels, Knauf panels - Alba board, plaster, metals etc. For wall surfaces, our coating is fully compatible with any stable substrate, subject to specific preparation.

IMPORTANT: Essential monitoring points: (resulting from our experience following errors encountered in the implementation of the microcement coating).

- Expansion joints often poorly placed (especially on door sills).

- Non-conforming expansion joints (screed segments must be separated and doweled. The edge strip must be visible on the surface of the joint).

- Poor coordination of surface thicknesses according to adjacent coatings.

- Lack of flatness.

- Quality, resistance of the surface questionable.

- Oversized surface segment.

- Poor workmanship in the laying of the edge strips on the periphery of the surface.

- Non-compliant ambient temperature.

Our recommendations are based on tests and practical experience over several years. The data and results can be influenced according to the conditions of implementation.

All details presented are given for information purposes only and do not represent an engagement of responsibility. These data cannot therefore be used as a basis for assessment of reparations.